SCADA – Supervisory Control and Data Acquisition

A Closed loop control system has a Sensor-Controller-Actuator. The Bimetal Thermostat has all the three in the Bimetal itself. The Sensor, the Relay Contact and the Intelligence. This is Process Control when implemented to control the temperature in a Bakery Oven.

This leads us to Sensors-Transmitter-Controller-Outputs-Actuators. Where each is an independent electronic/electrical component of an entire Process Control system. The Process could be Temperature, Pressure, Speed, or Level.

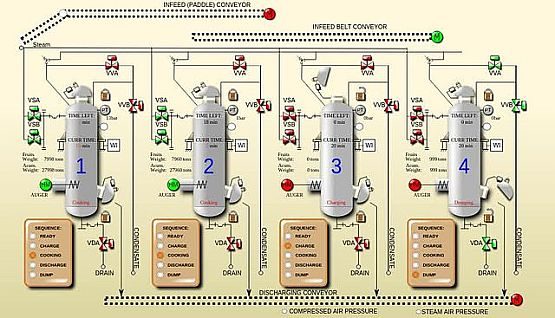

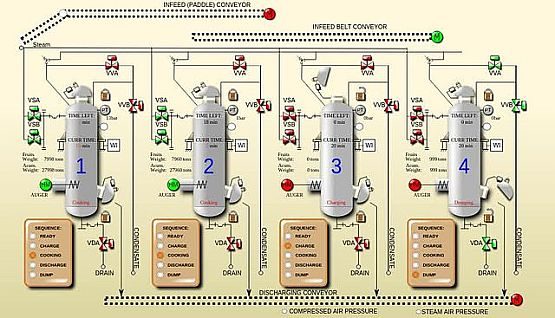

Industrial Automation encompasses many such Process Control Systems to form a Engineered System Solution for an Entire production line with different stages and process types.

At the machine end, the control has to be real time and highly reliable, dedicated controllers both Analog and Microcontrollers based are used. Analog as a fallback/override/trip or backup controller in case Embedded system gets stuck/fails.

These controllers or transmitters also send the data of the process back to a center control panel room. The actuators and outputs also have an override from the control panel. Sometimes Intelligent controllers at machine end can be remotely tweaked/tuned by Control room. This is possible due to Embedded systems and Flash., It also can pose problems if misused. Using SCADA such networking of these process control systems and Monitoring, Tweaking, Data Collection and Analysis is possible.

Come Internet or Web and Wireless, the scenario changes entirely. The Control room stays where it is, the Tablets can Access and utilize the SCADA and entire plant at the machine end also. The Control room can be carried around with limited access. This evolves further to that extent that an expert engineer can check the status of the Product Line from any Web Browser and suggest remedial actions to the others at the factory. He can even see the status on mobile devices. Now study the Resources below.

Industrial Process parameters, production flow or work status, material offtake, processing of products, incoming inspection status and quality process monitoring. All these need to be interfaced with the ERP and access to Mobile devices like Smartphones and remote Computers provided. This helps smooth micro management of a industry. Some Interfaces may have supervisory control and others just graphs and progress charts. Depending on the person and his work or machine area.

The data and presentation of complex data (by graphs and charts) enhances analysis and timely decision making. Then these solutions will be productive, and be an asset to an existing system. To ensure that; software or webware developers have to be supported by the domain experts having decades of hands on experience on the shop floor. Else; if it is built on theory and some statistics, the result may appear good and work well for small or standard configurations, but in demanding, changing, real life scenario, it may fail to deliver the best.